Jan 08,2026

Exploring the Benefits of Large Forged Components in Metalworking

Exploring the Benefits of Large Forged Components in Metalworking Introduction to Large Forged Components In the realm of **metalworking**, large forged components stand out as critical elements that can significantly enhance various industrial applications. These components, produced through the forging process, showcase remarkable properties that contribute to improved performance, durability, a

Key words:

Jan 05,2026

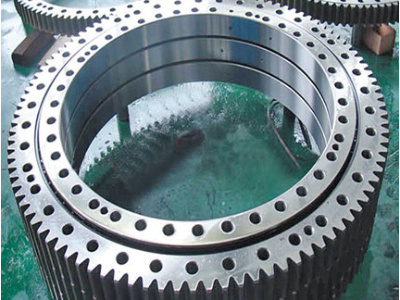

The Essential Guide to Forged Gear Rings: Understanding Their Manufacturing and Benefits

Forged gear rings are crucial components widely used in various mechanical applications, especially within the metalworking and manufacturing sectors. Their durability and strength make them ideal for gear systems that require high precision and resilience under stress. Understanding the characteristics and benefits of forged gear rings can aid in making informed choices in machinery design and ap

Key words:

Dec 29,2025

Unlocking Efficiency: The Role of Forged Gear Rings in Modern Machinery

Unlocking Efficiency: The Role of Forged Gear Rings in Modern Machinery Table of Contents 1. Introduction to Forged Gear Rings 2. Understanding the Manufacturing Process of Forged Gear Rings 2.1 The Importance of Raw Materials 2.2 The Forging Process Explained 2.3 Quality Control in Gear Ring Production 3. Key Characteristics of Forged Gear Rings 4. Applications of Forged Gear Rings in Various Ind

Key words:

Dec 25,2025

CNC Aluminum Machining: Precision Solutions for Modern Manufacturing

CNC aluminum machining delivers precise, high quality components with complex shapes, ensuring durability, efficiency, and reliability in modern manufacturing.

Key words:

Dec 22,2025

Understanding Flanges for Pressure Piping: Essential Components in Construction

Flanges are mechanical components used to connect two sections of piping or equipment in pressure piping systems. They play a vital role in ensuring the integrity and efficiency of fluid transport systems across various industries, including oil and gas, water treatment, and chemical processing. Understanding the importance of flanges for pressure piping is crucial for professionals in the constru

Key words:

Dec 18,2025

Large Diameter Ring Forging: Essential Components for Heavy Industry

Large diameter ring forging provides strong, durable components for heavy machinery and turbines, ensuring reliability and long term performance.

Key words:

Dec 15,2025

Understanding the Critical Role of Flanges in Pressure Piping Systems

Understanding the Critical Role of Flanges in Pressure Piping Systems Table of Contents 1. Introduction to Flanges and Their Importance 2. Types of Flanges Used in Pressure Piping 3. Materials and Design Considerations for Flanges 4. Proper Installation Techniques for Flanges 5. Maintenance Strategies for Flanges in Pressure Piping 6. Troubleshooting Common Flange Issu

Key words:

Dec 11,2025

Steel Ring Forging for Wind Power: Key Component for Turbine Reliability

Steel ring forging for wind power ensures strong, durable components for turbines, supporting reliable operation and long term energy production.

Key words:

Dec 08,2025

Understanding Flanges for Pressure Piping: Essential Insights for Your Construction Needs

Flanges are integral components in pressure piping systems, serving as the connection points between various sections of pipes, valves, and other equipment. Their primary purpose is to ensure a secure and leak-proof joint that can withstand the high pressures and temperatures often associated with industrial applications. Understanding the different types and functions of flanges is essential for

Key words:

Dec 04,2025

The Critical Role of Flanges for Pressure Piping in Industrial Systems

Flanges for pressure piping provide secure, leak proof connections in high pressure pipelines, ensuring safety, reliability, and efficient fluid flow.

Key words: