Exploring the Benefits of Stainless Steel Forged Rings for Wind Turbines

Release Time:

Jul 25,2025

Stainless steel forged rings play a crucial role in the construction and functionality of wind turbines. These rings are primarily used in various applications within the turbine assembly, including the main shaft, gearbox, and rotor connections. The durability and strength of stainless steel make it an ideal material for these components, as wind turbines are subjected to extreme environmental co

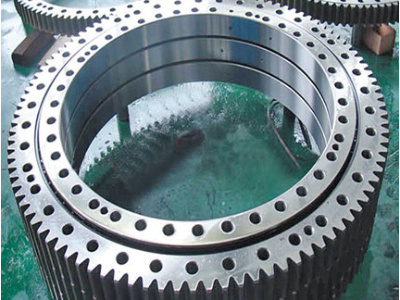

Stainless steel forged rings play a crucial role in the construction and functionality of wind turbines. These rings are primarily used in various applications within the turbine assembly, including the main shaft, gearbox, and rotor connections. The durability and strength of stainless steel make it an ideal material for these components, as wind turbines are subjected to extreme environmental conditions and mechanical stresses.

The forging process enhances the material properties of stainless steel, resulting in superior toughness and resistance to fatigue. During forging, the metal is heated and shaped under high pressure, aligning its internal grain structure. This process not only increases the structural integrity of the rings but also improves their performance under varying loads. As wind turbines are often located in remote areas, the reliability of each component is paramount to ensure uninterrupted energy production.

Another significant advantage of stainless steel forged rings is their resistance to corrosion. Wind turbines are frequently exposed to moisture, salt, and other corrosive agents, especially in coastal regions. The inherent properties of stainless steel, combined with the forging process, allow these rings to withstand harsh conditions without compromising their integrity. This aspect is vital for minimizing maintenance costs and extending the lifespan of the turbines.

In addition to their mechanical properties, stainless steel forged rings can also be precisely tailored to meet specific design requirements. Modern manufacturing techniques allow for custom specifications, ensuring that each ring fits perfectly within the turbine assembly. This customization is essential for optimizing the overall performance of the wind turbine, enhancing energy efficiency and reducing noise levels during operation.

Furthermore, the sustainability of stainless steel as a material aligns with the environmentally friendly goals of wind energy. Stainless steel is recyclable, making it a responsible choice for manufacturers and energy producers committed to reducing their ecological footprint. The production process for stainless steel also continues to evolve, with innovations focused on reducing energy consumption and greenhouse gas emissions.

In conclusion, stainless steel forged rings are vital components in the construction of wind turbines. Their strength, corrosion resistance, and customization capabilities contribute significantly to the efficiency and reliability of renewable energy systems. As the demand for sustainable energy solutions continues to grow, the role of quality materials such as stainless steel will remain indispensable in the advancement of wind technology. Investing in high-quality forged rings can lead to improved performance and longevity of wind turbines, supporting the global shift toward cleaner energy sources.

The forging process enhances the material properties of stainless steel, resulting in superior toughness and resistance to fatigue. During forging, the metal is heated and shaped under high pressure, aligning its internal grain structure. This process not only increases the structural integrity of the rings but also improves their performance under varying loads. As wind turbines are often located in remote areas, the reliability of each component is paramount to ensure uninterrupted energy production.

Another significant advantage of stainless steel forged rings is their resistance to corrosion. Wind turbines are frequently exposed to moisture, salt, and other corrosive agents, especially in coastal regions. The inherent properties of stainless steel, combined with the forging process, allow these rings to withstand harsh conditions without compromising their integrity. This aspect is vital for minimizing maintenance costs and extending the lifespan of the turbines.

In addition to their mechanical properties, stainless steel forged rings can also be precisely tailored to meet specific design requirements. Modern manufacturing techniques allow for custom specifications, ensuring that each ring fits perfectly within the turbine assembly. This customization is essential for optimizing the overall performance of the wind turbine, enhancing energy efficiency and reducing noise levels during operation.

Furthermore, the sustainability of stainless steel as a material aligns with the environmentally friendly goals of wind energy. Stainless steel is recyclable, making it a responsible choice for manufacturers and energy producers committed to reducing their ecological footprint. The production process for stainless steel also continues to evolve, with innovations focused on reducing energy consumption and greenhouse gas emissions.

In conclusion, stainless steel forged rings are vital components in the construction of wind turbines. Their strength, corrosion resistance, and customization capabilities contribute significantly to the efficiency and reliability of renewable energy systems. As the demand for sustainable energy solutions continues to grow, the role of quality materials such as stainless steel will remain indispensable in the advancement of wind technology. Investing in high-quality forged rings can lead to improved performance and longevity of wind turbines, supporting the global shift toward cleaner energy sources.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot