Understanding Medium and Large-Size Forged and Machined Parts in Metalworking

Release Time:

Jul 20,2025

In the realm of metalworking, medium and large-size forged and machined parts play an integral role in the production of various machinery and equipment. These components are critical in industries such as automotive, aerospace, construction, and energy. Understanding the properties and manufacturing processes of these parts can significantly enhance their application and performance in complex sy

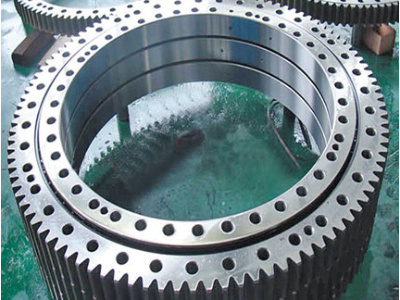

In the realm of metalworking, medium and large-size forged and machined parts play an integral role in the production of various machinery and equipment. These components are critical in industries such as automotive, aerospace, construction, and energy. Understanding the properties and manufacturing processes of these parts can significantly enhance their application and performance in complex systems.

Forging is a manufacturing process that involves shaping metal by applying compressive forces. This technique is particularly beneficial for producing large components due to its ability to refine the grain structure of the metal, resulting in improved strength and durability. When it comes to medium and large-size forged parts, the process typically employs techniques like open-die forging, closed-die forging, and die forging. Each of these methods offers distinct advantages depending on the specific requirements of the part being produced.

Machining, complementing the forging process, involves the removal of material to achieve desired dimensions and finishes. This step is crucial for ensuring that the forged parts meet precise specifications and tolerances. Machining processes may include turning, milling, drilling, and grinding, each of which contributes to the final quality and functionality of the finished component.

One of the primary advantages of medium and large-size forged and machined parts is their ability to endure extreme operational conditions. The high strength-to-weight ratio and enhanced structural integrity make these parts ideal for high-stress applications. Additionally, the forging process often results in a uniform grain structure, which contributes to improved fatigue resistance and overall performance.

Moreover, the versatility of these components allows them to be tailored for various applications. For instance, in the automotive sector, large forged parts such as crankshafts and connecting rods are essential for engine performance. In the aerospace industry, components like landing gear and structural frames benefit from the high strength and reliability offered by forged parts.

The importance of quality control in the production of medium and large-size forged and machined parts cannot be overstated. Rigorous testing and inspection processes are essential to ensure that each component meets industry standards and customer specifications. This attention to detail not only enhances the safety and reliability of the final product but also boosts the reputation of the manufacturers involved.

In conclusion, medium and large-size forged and machined parts are vital components in the metalworking industry, providing strength, durability, and precision. As technology continues to evolve, the processes used to create these parts will also advance, leading to even greater improvements in efficiency and performance. Understanding these components and their manufacturing processes is crucial for professionals in the field seeking to leverage their potential in various applications.

Forging is a manufacturing process that involves shaping metal by applying compressive forces. This technique is particularly beneficial for producing large components due to its ability to refine the grain structure of the metal, resulting in improved strength and durability. When it comes to medium and large-size forged parts, the process typically employs techniques like open-die forging, closed-die forging, and die forging. Each of these methods offers distinct advantages depending on the specific requirements of the part being produced.

Machining, complementing the forging process, involves the removal of material to achieve desired dimensions and finishes. This step is crucial for ensuring that the forged parts meet precise specifications and tolerances. Machining processes may include turning, milling, drilling, and grinding, each of which contributes to the final quality and functionality of the finished component.

One of the primary advantages of medium and large-size forged and machined parts is their ability to endure extreme operational conditions. The high strength-to-weight ratio and enhanced structural integrity make these parts ideal for high-stress applications. Additionally, the forging process often results in a uniform grain structure, which contributes to improved fatigue resistance and overall performance.

Moreover, the versatility of these components allows them to be tailored for various applications. For instance, in the automotive sector, large forged parts such as crankshafts and connecting rods are essential for engine performance. In the aerospace industry, components like landing gear and structural frames benefit from the high strength and reliability offered by forged parts.

The importance of quality control in the production of medium and large-size forged and machined parts cannot be overstated. Rigorous testing and inspection processes are essential to ensure that each component meets industry standards and customer specifications. This attention to detail not only enhances the safety and reliability of the final product but also boosts the reputation of the manufacturers involved.

In conclusion, medium and large-size forged and machined parts are vital components in the metalworking industry, providing strength, durability, and precision. As technology continues to evolve, the processes used to create these parts will also advance, leading to even greater improvements in efficiency and performance. Understanding these components and their manufacturing processes is crucial for professionals in the field seeking to leverage their potential in various applications.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot