Why Choose Forged and Machined Parts for Heavy Industries?

Release Time:

Jul 23,2025

Why Choose Forged and Machined Parts for Heavy Industries? A Comprehensive Overview of Forged and Machined Parts In the realm of heavy industries, the choice of components can significantly impact the performance and durability of machinery. **Forged and machined parts** have emerged as a top choice due to their superior strength and longevity. This article delves into the pivotal reasons for ch

Why Choose Forged and Machined Parts for Heavy Industries?

A Comprehensive Overview of Forged and Machined Parts

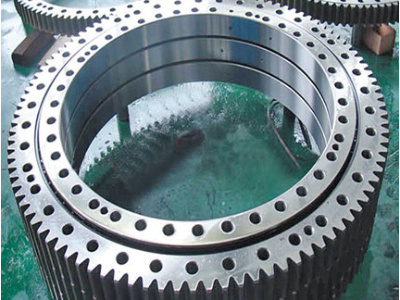

In the realm of heavy industries, the choice of components can significantly impact the performance and durability of machinery. **Forged and machined parts** have emerged as a top choice due to their superior strength and longevity. This article delves into the pivotal reasons for choosing these components, emphasizing their applications and advantages in various heavy industrial sectors.

Understanding Forging and Machining

Forging and machining are two fundamental processes used in the production of components for heavy industries.

What is Forging?

Forging involves shaping metal through localized compressive forces, often utilizing hammers or presses. This process aligns the metal's internal grain structure, enhancing its **strength and toughness**. There are various types of forging methods, including:

- **Open-die forging**: Ideal for large components.

- **Closed-die forging**: Suitable for high-precision parts.

- **Roll forging**: Efficient for creating long, thin parts.

What is Machining?

Machining refers to the process of removing material from a workpiece to achieve desired dimensions and surface finishes. Techniques like turning, milling, drilling, and grinding are commonly employed. Machined parts often exhibit tight tolerances and superior surface finishes, making them ideal for high-performance applications.

The Benefits of Forged and Machined Parts in Heavy Industries

When it comes to heavy industries such as construction, mining, and transportation, **forged and machined parts** provide numerous advantages that can significantly enhance operational efficiency and reliability.

1. Enhanced Strength and Durability

One of the most compelling reasons for choosing forged components is their **superior strength**. The forging process increases toughness and fatigue resistance, which is crucial for components subjected to high stress and harsh environments. Machined parts, with their precise dimensions, also ensure better fit and function, minimizing wear and extending service life.

2. Cost-Effectiveness Over Time

While the initial cost of forged and machined parts may be higher than alternative options, the long-term savings are undeniable. Their durability leads to less frequent replacements and repairs, reducing operational downtime. Additionally, fewer failures mean decreased maintenance costs, contributing to overall cost-effectiveness.

3. Customization and Precision

Heavy industries often require bespoke solutions tailored to specific applications. Both forging and machining processes allow for a high degree of customization. Manufacturers can create components in a variety of shapes and sizes, achieving tight tolerances that enhance performance. This flexibility means that companies can adapt their machinery to meet evolving demands.

4. Improved Safety Standards

Using high-quality forged and machined parts directly contributes to enhanced safety in heavy industries. These components are designed to withstand extreme conditions and reduce the likelihood of catastrophic failures. By investing in reliable machinery, organizations ensure the safety of their workforce and the integrity of their operations.

Applications of Forged and Machined Parts in Heavy Industries

Forged and machined parts find uses in a wide array of heavy industrial applications. Here, we explore some notable examples.

1. Construction Equipment

Heavy machinery like excavators and bulldozers relies heavily on forged and machined components. These parts are essential for maintaining strength and durability under demanding conditions.

2. Mining Machinery

In the mining sector, equipment must endure extreme wear and tear. Forged and machined parts offer the required toughness to withstand abrasive environments and heavy loads.

3. Aerospace and Defense

In aerospace, precision and reliability are paramount. Forged and machined components are critical in aircraft engines and structural components, where performance and safety are non-negotiable.

4. Automotive Industry

The automotive industry utilizes forged and machined parts in various applications, from engine blocks to suspension systems. The strength and precision of these components play a crucial role in vehicle performance and safety.

The Manufacturing Process: From Raw Material to Finished Product

Understanding the manufacturing process of forged and machined parts sheds light on their quality.

1. Material Selection

The journey begins with the selection of appropriate materials, typically high-strength alloys that can withstand the forging and machining processes. Common materials include carbon steel, alloy steel, and stainless steel.

2. Forging Process

Once the material is selected, it undergoes **heating** and **forging**. The metal is heated to a malleable state and shaped using various forging methods. This process strengthens the material through grain refinement.

3. Machining Operations

After forging, the component is machined to achieve precise dimensions and surface finishes. Advanced CNC (Computer Numerical Control) machines are often employed for their accuracy and consistency.

4. Quality Control

Quality assurance is critical in the production of forged and machined parts. Rigorous testing ensures that each component meets industry standards and specifications, ensuring reliability and performance.

Choosing the Right Supplier for Forged and Machined Parts

Selecting a reliable supplier is vital for obtaining high-quality forged and machined parts. Here are key factors to consider:

1. Industry Experience

Choose a supplier with extensive experience in your specific industry. Their knowledge of industry requirements and standards will ensure that your components meet all necessary specifications.

2. Manufacturing Capabilities

Evaluate the supplier's manufacturing capabilities. Do they have advanced machinery and technology? Can they produce custom parts to your specifications? A capable supplier will have the resources to meet your demands.

3. Certifications and Compliance

Ensure that the supplier complies with relevant industry standards and holds necessary certifications. This compliance is crucial for maintaining quality and safety in your operations.

4. Customer Reviews and References

Research customer reviews and ask for references. Feedback from past clients can provide insights into the supplier's reliability, product quality, and customer service.

FAQs about Forged and Machined Parts

1. What are the primary advantages of forged parts over cast parts?

Forged parts generally offer higher strength, improved grain structure, and better fatigue resistance compared to cast parts. This makes them more suitable for applications where durability and reliability are critical.

2. How do machining processes improve the performance of parts?

Machining processes enhance the precision and surface finish of parts, ensuring they fit together correctly and operate efficiently. This precision reduces wear and tear, contributing to longer service life.

3. Can forged parts be customized for specific applications?

Yes, forged parts can be customized in terms of shape, size, and material properties to meet specific application requirements, ensuring optimal performance.

4. What materials are commonly used for forged and machined parts?

Common materials include carbon steel, alloy steel, stainless steel, and titanium. The choice of material depends on the application and desired properties.

5. How do I ensure the quality of forged and machined parts?

To ensure quality, work with reputable suppliers that adhere to industry standards and perform rigorous quality control testing on their products.

Conclusion

In summary, the selection of forged and machined parts is a crucial decision for heavy industries looking to enhance their operational efficiency and reliability. With their exceptional strength, durability, and customization options, these components are well-suited for various applications, ranging from construction equipment to aerospace. By investing in high-quality forged and machined parts, companies can realize significant long-term benefits, ensuring safety, reducing maintenance costs, and optimizing performance. Choosing the right supplier will further amplify these advantages, leading to a more successful and sustainable operation in the demanding landscape of heavy industries.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot