Understanding Shaft Forgings: A Key Component in Metal Processing Machinery

Release Time:

Jul 02,2025

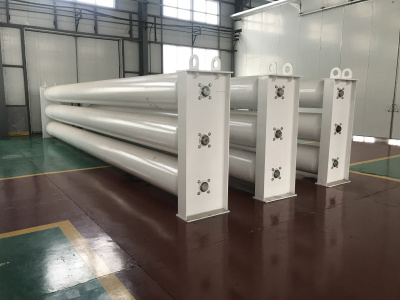

Shaft forgings are essential components used in various machinery, particularly in the metal processing and machining sectors. These parts are typically made from high-strength materials through a process that involves shaping heated metal using compressive forces. This method not only enhances the mechanical properties of the material but also allows for complex shapes to be formed, which are vit

Shaft forgings are essential components used in various machinery, particularly in the metal processing and machining sectors. These parts are typically made from high-strength materials through a process that involves shaping heated metal using compressive forces. This method not only enhances the mechanical properties of the material but also allows for complex shapes to be formed, which are vital for the operational efficiency of many machines.

The forging process begins with selecting the appropriate metal, commonly steel or alloys, known for their durability and resistance to wear. The metal is then heated to a malleable state and placed into a forging die. By applying pressure, the metal is deformed into the desired shape, which can include features like keyways, splines, or tapering. This process creates a grain structure that is aligned with the shape of the shaft, improving its strength and fatigue resistance compared to cast or machined parts.

One of the primary advantages of shaft forgings is their superior mechanical properties. The forging process enhances the grain flow of the metal, resulting in a part that can withstand high stress and loads. This characteristic is particularly important for components used in heavy machinery, where reliability and durability are paramount. Additionally, forged shafts exhibit better impact resistance, making them suitable for applications where sudden loads may occur.

Shaft forgings are widely used in various applications, including automotive, aerospace, and industrial machinery. In the automotive industry, for example, forged shafts are commonly found in drivetrains, where they must transmit power efficiently while enduring heavy loads. In aerospace, they are utilized in engine components, where high strength-to-weight ratios are critical for performance.

Moreover, the versatility of shaft forgings allows them to be customized to meet specific requirements. Manufacturers can tailor the dimensions, material properties, and surface finishes to align with the operational conditions of the equipment. This adaptability ensures that the shafts perform optimally in their intended applications, enhancing the overall efficiency of the machinery they are part of.

In summary, shaft forgings are integral to the metal processing and manufacturing industries. Their production through forging not only improves material properties but also enables the creation of complex geometries required for modern machinery. As industries continue to evolve, the importance of high-quality shaft forgings will remain significant in ensuring that machinery operates effectively and reliably under various conditions. Understanding the intricacies of shaft forgings can help manufacturers make informed choices that benefit their operations and product performance.

The forging process begins with selecting the appropriate metal, commonly steel or alloys, known for their durability and resistance to wear. The metal is then heated to a malleable state and placed into a forging die. By applying pressure, the metal is deformed into the desired shape, which can include features like keyways, splines, or tapering. This process creates a grain structure that is aligned with the shape of the shaft, improving its strength and fatigue resistance compared to cast or machined parts.

One of the primary advantages of shaft forgings is their superior mechanical properties. The forging process enhances the grain flow of the metal, resulting in a part that can withstand high stress and loads. This characteristic is particularly important for components used in heavy machinery, where reliability and durability are paramount. Additionally, forged shafts exhibit better impact resistance, making them suitable for applications where sudden loads may occur.

Shaft forgings are widely used in various applications, including automotive, aerospace, and industrial machinery. In the automotive industry, for example, forged shafts are commonly found in drivetrains, where they must transmit power efficiently while enduring heavy loads. In aerospace, they are utilized in engine components, where high strength-to-weight ratios are critical for performance.

Moreover, the versatility of shaft forgings allows them to be customized to meet specific requirements. Manufacturers can tailor the dimensions, material properties, and surface finishes to align with the operational conditions of the equipment. This adaptability ensures that the shafts perform optimally in their intended applications, enhancing the overall efficiency of the machinery they are part of.

In summary, shaft forgings are integral to the metal processing and manufacturing industries. Their production through forging not only improves material properties but also enables the creation of complex geometries required for modern machinery. As industries continue to evolve, the importance of high-quality shaft forgings will remain significant in ensuring that machinery operates effectively and reliably under various conditions. Understanding the intricacies of shaft forgings can help manufacturers make informed choices that benefit their operations and product performance.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot