Understanding Stationary LNG Storage Vessels: Key Insights for Industrial Applications

Release Time:

Jun 26,2025

Stationary LNG storage vessels are integral components in the infrastructure for handling liquefied natural gas, a cleaner-burning alternative to traditional fossil fuels. These vessels are specifically designed to store LNG at cryogenic temperatures, typically around -162 degrees Celsius (-260 degrees Fahrenheit). Their primary purpose is to ensure the safe containment of LNG until it is ready fo

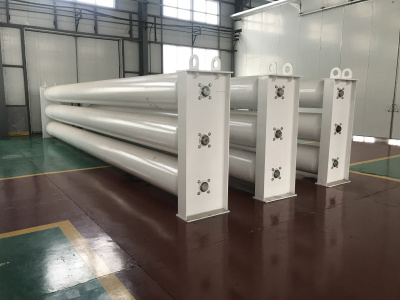

Stationary LNG storage vessels are integral components in the infrastructure for handling liquefied natural gas, a cleaner-burning alternative to traditional fossil fuels. These vessels are specifically designed to store LNG at cryogenic temperatures, typically around -162 degrees Celsius (-260 degrees Fahrenheit). Their primary purpose is to ensure the safe containment of LNG until it is ready for distribution or regasification.

One of the key features of stationary LNG storage vessels is their design. They are typically constructed from materials that can withstand extreme cold and pressure, such as high-strength steel. These materials ensure that the LNG remains in a liquid state and helps prevent any potential leaks. The vessels are often insulated to minimize heat transfer, which is vital for maintaining the LNG’s temperature and state.

Safety is paramount in the design and operation of stationary LNG storage vessels. Various safety mechanisms are incorporated to prevent overpressure, spills, and other potential hazards. For instance, pressure relief valves are installed to allow the safe release of gas in case of pressure increases. Additionally, modern stationary LNG storage vessels are equipped with advanced monitoring systems that continuously track temperature, pressure, and structural integrity to ensure operational safety.

From an operational perspective, stationary LNG storage vessels facilitate the seamless flow of natural gas from production sites to consumers. These vessels serve as a buffer, enabling the storage of LNG during periods of low demand and its subsequent release during peak consumption times. This flexibility is essential in balancing supply and demand, particularly in regions where natural gas consumption can fluctuate significantly.

Moreover, stationary LNG storage vessels can vary in size and capacity, depending on the needs of the facility. Smaller vessels might be used for localized applications, such as industrial plants, while larger vessels are often found in terminals that serve broader distribution networks. The choice of vessel size and design will depend on factors like usage frequency, regional regulations, and logistical considerations.

In conclusion, stationary LNG storage vessels are a vital component of the natural gas supply chain. Their specialized design, safety features, and operational efficiency contribute to the successful storage and distribution of liquefied natural gas. As the demand for cleaner energy sources continues to grow, understanding the role of these storage vessels becomes increasingly important for industry stakeholders and environmental advocates alike.

One of the key features of stationary LNG storage vessels is their design. They are typically constructed from materials that can withstand extreme cold and pressure, such as high-strength steel. These materials ensure that the LNG remains in a liquid state and helps prevent any potential leaks. The vessels are often insulated to minimize heat transfer, which is vital for maintaining the LNG’s temperature and state.

Safety is paramount in the design and operation of stationary LNG storage vessels. Various safety mechanisms are incorporated to prevent overpressure, spills, and other potential hazards. For instance, pressure relief valves are installed to allow the safe release of gas in case of pressure increases. Additionally, modern stationary LNG storage vessels are equipped with advanced monitoring systems that continuously track temperature, pressure, and structural integrity to ensure operational safety.

From an operational perspective, stationary LNG storage vessels facilitate the seamless flow of natural gas from production sites to consumers. These vessels serve as a buffer, enabling the storage of LNG during periods of low demand and its subsequent release during peak consumption times. This flexibility is essential in balancing supply and demand, particularly in regions where natural gas consumption can fluctuate significantly.

Moreover, stationary LNG storage vessels can vary in size and capacity, depending on the needs of the facility. Smaller vessels might be used for localized applications, such as industrial plants, while larger vessels are often found in terminals that serve broader distribution networks. The choice of vessel size and design will depend on factors like usage frequency, regional regulations, and logistical considerations.

In conclusion, stationary LNG storage vessels are a vital component of the natural gas supply chain. Their specialized design, safety features, and operational efficiency contribute to the successful storage and distribution of liquefied natural gas. As the demand for cleaner energy sources continues to grow, understanding the role of these storage vessels becomes increasingly important for industry stakeholders and environmental advocates alike.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot