Best Blind Flanges For Lng Systems

Release Time:

Jun 18,2025

Blind flanges for LNG systems serve as a vital safety barrier in cryogenic piping networks, ensuring secure isolation during maintenance or emergency shutdowns. Engineered for ultra-low-temperature applications, these flanges are constructed from austenitic stainless steel (e.g., 304L, 316L) or specialized alloys like Inconel to resist brittleness and thermal stress in LNG environments. Their leak-tight design prevents fugitive emissions, maintaining operational integrity in gas processing and distribution systems.

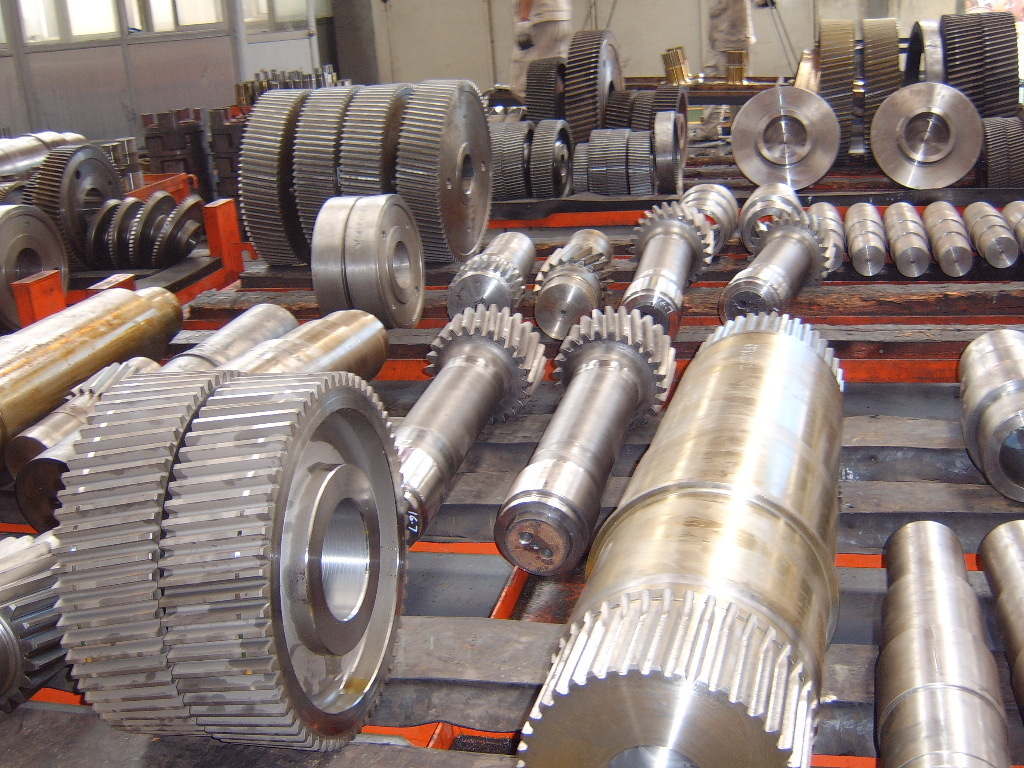

We produce flanges, which are efficient connectors between pipelines, equipment or machinery. They can achieve sealing, support or disassembly functions to ensure the safety and stability of the system.

Product advantages

● Diverse types

Flat welding flanges, butt welding flanges, blind flanges, threaded flanges, etc. are available to meet different working conditions.

● Precision sealing

High-precision processing ensures that the sealing surface (such as raised surface RF, flat surface FF) and the gasket fit perfectly to prevent leakage.

● Material adaptation

Carbon steel, stainless steel, alloy steel, etc. are optional to meet harsh environments such as corrosion, high temperature and high pressure.

Typical applications

● Petrochemical pipeline connection

● General pipeline connection

● Modular assembly of ships and heavy machinery

● Wind power tower connection

Blind flanges for LNG systems serve as a vital safety barrier in cryogenic piping networks, ensuring secure isolation during maintenance or emergency shutdowns. Engineered for ultra-low-temperature applications, these flanges are constructed from austenitic stainless steel (e.g., 304L, 316L) or specialized alloys like Inconel to resist brittleness and thermal stress in LNG environments. Their leak-tight design prevents fugitive emissions, maintaining operational integrity in gas processing and distribution systems.

The manufacturing process of blind flanges for LNG systems involves advanced forging techniques, followed by deep-freeze stabilization to enhance material stability. Each flange undergoes non-destructive testing (NDT), including ultrasonic and radiographic inspection, to detect potential defects. Furthermore, they feature serrated or smooth raised faces (RF/FF) with spiral-wound gaskets for optimal sealing under fluctuating pressures.

Due to their critical role in LNG infrastructure, these flanges are widely deployed in liquefaction plants, bunkering stations, and floating storage units (FSUs). Their compatibility with high-pressure LNG pipelines and resistance to cryogenic embrittlement make them indispensable for ensuring system safety. Whether used in temporary closures or permanent installations, blind flanges for LNG systems deliver unmatched performance, compliance with industry standards, and operational longevity.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot