Understanding the Critical Role of Flanges in Pressure Piping Systems

Release Time:

Dec 15,2025

Understanding the Critical Role of Flanges in Pressure Piping Systems Table of Contents 1. Introduction to Flanges and Their Importance 2. Types of Flanges Used in Pressure Piping 3. Materials and Design Considerations for Flanges 4. Proper Installation Techniques for Flanges 5. Maintenance Strategies for Flanges in Pressure Piping 6. Troubleshooting Common Flange Issu

Understanding the Critical Role of Flanges in Pressure Piping Systems

Table of Contents

- 1. Introduction to Flanges and Their Importance

- 2. Types of Flanges Used in Pressure Piping

- 3. Materials and Design Considerations for Flanges

- 4. Proper Installation Techniques for Flanges

- 5. Maintenance Strategies for Flanges in Pressure Piping

- 6. Troubleshooting Common Flange Issues

- 7. Regulatory Standards and Compliance for Flanges

- 8. Future Trends in Flange Technology and Applications

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Flanges and Their Importance

Flanges are essential components in pressure piping systems, serving as a means of joining two sections of pipe or connecting piping to other equipment. They not only provide structural support but also enable maintenance and inspection. Understanding the role of flanges is crucial for engineers and contractors to ensure the integrity and efficiency of piping systems.

Flanges facilitate ease of assembly and disassembly, which is vital for systems requiring frequent maintenance. Moreover, they are designed to handle high-pressure and temperature variations, making them indispensable in various industries such as oil and gas, chemical processing, and water treatment.

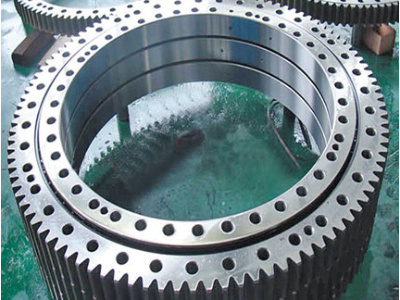

2. Types of Flanges Used in Pressure Piping

Flanges come in various types, each designed for specific applications. Here are some of the most common types of flanges used in pressure piping:

2.1 Weld Neck Flanges

Weld neck flanges are characterized by a long neck that gradually tapers to meet the pipe. This design provides a strong connection, making them ideal for high-pressure applications. They are widely used in industries like petrochemical and power generation.

2.2 Slip-On Flanges

Slip-on flanges are designed to slide over the end of the pipe. They are easier to align and fit, making them popular in low-pressure applications. However, they are not generally recommended for high-pressure systems due to their lower strength compared to weld neck flanges.

2.3 Blind Flanges

Blind flanges are solid, with no central opening. They are used to close off ends of piping systems, providing a secure seal. Their strength makes them suitable for high-pressure environments, where they can withstand significant force.

2.4 Socket Weld Flanges

Socket weld flanges are used for small-diameter piping and are welded to the pipe at a socket joint. This type ensures a strong connection and is often used in high-pressure and high-temperature applications.

2.5 Threaded Flanges

Threaded flanges have internal threads that allow them to be screwed onto pipes. They are beneficial in situations where welding is not feasible, but they are less robust than welded flanges and are usually limited to lower pressure applications.

3. Materials and Design Considerations for Flanges

Choosing the right material for flanges is critical for their performance and longevity. Here are some commonly used materials:

3.1 Carbon Steel

Carbon steel flanges are known for their strength and durability. They are suitable for a wide range of applications, particularly in oil and gas industries. However, they may require protective coatings to prevent corrosion.

3.2 Stainless Steel

Stainless steel flanges offer excellent corrosion resistance, making them ideal for chemical processing and marine applications. They maintain strength at high temperatures and are preferred for hygienic applications due to their easy cleaning properties.

3.3 Alloy Steel

Alloy steel flanges are designed to withstand extreme conditions, such as high temperatures and pressures. They are often used in power plants and heavy industries due to their enhanced mechanical properties.

3.4 Plastic and Composite Materials

In specific applications, especially in water treatment and food processing, flanges made from plastic or composite materials are used. These materials resist corrosion and are lightweight, although they may not handle high pressures as effectively as metals.

4. Proper Installation Techniques for Flanges

The installation of flanges requires precision to ensure a leak-proof connection. Here are best practices for flange installation:

4.1 Clean the Flange Faces

Before installation, clean the flange faces to remove any debris, rust, or old gasket material. This step is crucial to achieving a tight seal.

4.2 Use Gaskets Appropriately

Select the right gasket material based on the fluid type, pressure, and temperature. Proper gasket installation is vital to prevent leaks.

4.3 Align the Flanges Correctly

Ensure that the flanges are aligned properly before tightening. Misalignment can lead to uneven stress distribution, resulting in potential failures.

4.4 Tightening Sequence

Follow a crisscross pattern when tightening bolts to ensure even pressure across the flange joint. This method minimizes the risk of warping and helps maintain the integrity of the seal.

5. Maintenance Strategies for Flanges in Pressure Piping

Regular maintenance of flanges is essential for ensuring their longevity and functionality. Here are some effective maintenance strategies:

5.1 Routine Inspections

Conduct regular inspections to check for signs of wear, corrosion, or leaks. Early detection of problems can prevent costly repairs and downtime.

5.2 Bolt Tightening Checks

Periodically check the bolt tightness and re-tighten as necessary. Flange joints can loosen over time due to thermal expansion and contraction.

5.3 Corrosion Protection

Apply corrosion-resistant coatings or wraps to protect flanges from environmental factors. This is particularly important in outdoor installations or corrosive environments.

5.4 Maintain Proper Operating Conditions

Ensure that the operating conditions (pressure and temperature) remain within the specifications for the flange material used. Exceeding these limits can lead to premature failure.

6. Troubleshooting Common Flange Issues

Despite best practices, issues can still arise with flanges. Here’s how to troubleshoot common problems:

6.1 Leaks

Leaks are the most common issue. Check for loose bolts, misalignment, or damaged gaskets. Tightening bolts may resolve minor leaks, but replacing gaskets might be necessary for severe cases.

6.2 Corrosion

If corrosion is present, assess the type of environment the flange is exposed to. Consider using more resistant materials or applying protective coatings.

6.3 Flange Misalignment

Misalignment can cause stress and lead to failure. Realign flanges and ensure they are properly fitted before re-tightening.

6.4 Bolted Joint Fatigue

Repeated thermal cycles can lead to fatigue in bolted joints. Consider using flange designs that accommodate movement or installing additional supports.

7. Regulatory Standards and Compliance for Flanges

Flanges must comply with various industry standards and regulations to ensure safety and reliability. Familiarizing yourself with these standards is critical:

7.1 ASME B16 Standards

The American Society of Mechanical Engineers (ASME) provides a series of standards for flanges, including dimensional specifications and material requirements.

7.2 API Standards

The American Petroleum Institute (API) outlines standards specifically for oil and gas applications, ensuring that flanges can withstand the demanding conditions of these industries.

7.3 ISO Standards

International Organization for Standardization (ISO) standards provide guidelines for the safety and quality of flanges used globally, promoting consistency in manufacturing and materials.

8. Future Trends in Flange Technology and Applications

The flange industry is evolving, with emerging technologies leading to innovations such as:

8.1 Smart Flanges

Integration of sensors in flanges for real-time monitoring of pressure and temperature is becoming more common. These smart flanges can help in predictive maintenance and reduce downtime.

8.2 Advanced Materials

The development of advanced composite materials promises to deliver stronger and lighter flanges that can withstand extreme conditions while reducing overall system weight.

8.3 Enhanced Manufacturing Techniques

Additive manufacturing (3D printing) is revolutionizing flange production, allowing for complex designs and rapid prototyping, which can lead to cost savings and innovation.

9. Frequently Asked Questions

9.1 What are the primary functions of flanges in pressure piping?

Flanges serve to connect piping sections, provide structural support, facilitate maintenance access, and ensure leak-proof seals under pressure conditions.

9.2 How do I choose the right flange for my application?

Consider factors such as pressure and temperature requirements, the type of fluid transported, and compatibility with existing piping materials when selecting a flange.

9.3 What maintenance is required for flanges?

Routine inspections, re-tightening bolts, checking for corrosion, and ensuring environmental conditions remain consistent are key aspects of flange maintenance.

9.4 Can flanges be reused after disassembly?

Flanges can be reused if they are in good condition, without deformation or damage. However, gaskets should be replaced to ensure a proper seal.

9.5 What are the consequences of a flange failure?

Flange failures can lead to leaks, system downtime, and potential safety hazards. Regular maintenance and proper installation are crucial to prevent such failures.

10. Conclusion

Flanges play a **crucial role** in pressure piping systems, ensuring connections that are both secure and efficient. Understanding the various types, materials, installation techniques, and maintenance strategies related to flanges can significantly impact the performance and safety of piping systems. With ongoing advancements in technology and materials, the future of flanges looks promising, enhancing reliability and functionality in diverse applications. By prioritizing proper installation and maintenance, we can ensure a long service life and optimal performance of flanges in any piping system.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot