Understanding Large Forged Gears for Oil Industry Applications

Release Time:

Aug 18,2025

Large forged gears are indispensable components in the oil industry, where they are utilized in various applications, including drilling rigs, pumps, and other heavy machinery. These gears are designed to handle substantial loads and resist wear and tear in demanding environments, characteristic of oil extraction and transportation processes. One of the primary advantages of using large forged gea

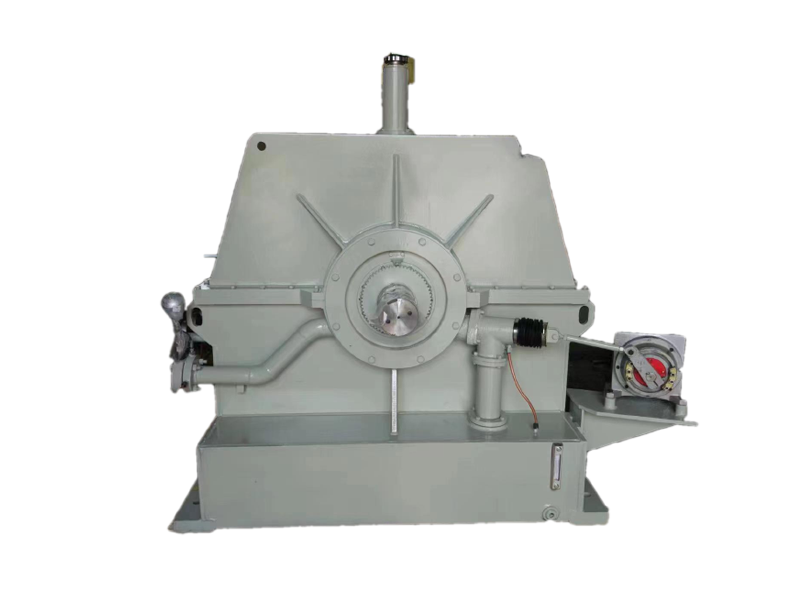

Large forged gears are indispensable components in the oil industry, where they are utilized in various applications, including drilling rigs, pumps, and other heavy machinery. These gears are designed to handle substantial loads and resist wear and tear in demanding environments, characteristic of oil extraction and transportation processes.

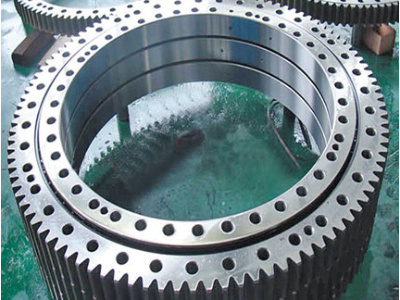

One of the primary advantages of using large forged gears is their ability to withstand high levels of stress. The forging process involves shaping metal under high pressure, resulting in a product that is not only strong but also has improved structural integrity compared to gears made through casting or machining. This enhanced durability is vital in the oil industry, where equipment often operates in harsh conditions, including extreme temperatures and corrosive environments.

Additionally, large forged gears can be customized to meet specific operational requirements. Their design can accommodate various gear ratios and configurations, allowing for optimal performance in equipment ranging from offshore drilling platforms to land-based extraction sites. The ability to tailor these gears ensures that oil companies can achieve maximum efficiency in their operations, minimizing downtime and maintenance costs.

Another significant aspect to consider is the material selection for these gears. Typically manufactured from high-quality alloy steels or other specialized materials, large forged gears exhibit excellent fatigue resistance and can endure the cyclic loads common in oil drilling applications. The selection of the right material not only enhances the gear's performance but also extends its lifespan, which is crucial for minimizing replacement frequency and associated costs.

In terms of maintenance, regular inspections and proper lubrication are essential for ensuring the longevity of large forged gears. Effective maintenance practices can prevent premature wear and failures, contributing to the overall reliability of the machinery they support. Utilizing advanced monitoring technologies can also aid in identifying potential issues before they lead to significant downtime.

In summary, large forged gears play a pivotal role in the oil industry, providing the strength, durability, and performance necessary for efficient operations. Their ability to withstand extreme conditions and customizable nature makes them ideal for various applications within the sector. By understanding the importance and benefits of these components, industry professionals can make informed decisions that enhance operational efficiency while ensuring the reliability and safety of their equipment.

One of the primary advantages of using large forged gears is their ability to withstand high levels of stress. The forging process involves shaping metal under high pressure, resulting in a product that is not only strong but also has improved structural integrity compared to gears made through casting or machining. This enhanced durability is vital in the oil industry, where equipment often operates in harsh conditions, including extreme temperatures and corrosive environments.

Additionally, large forged gears can be customized to meet specific operational requirements. Their design can accommodate various gear ratios and configurations, allowing for optimal performance in equipment ranging from offshore drilling platforms to land-based extraction sites. The ability to tailor these gears ensures that oil companies can achieve maximum efficiency in their operations, minimizing downtime and maintenance costs.

Another significant aspect to consider is the material selection for these gears. Typically manufactured from high-quality alloy steels or other specialized materials, large forged gears exhibit excellent fatigue resistance and can endure the cyclic loads common in oil drilling applications. The selection of the right material not only enhances the gear's performance but also extends its lifespan, which is crucial for minimizing replacement frequency and associated costs.

In terms of maintenance, regular inspections and proper lubrication are essential for ensuring the longevity of large forged gears. Effective maintenance practices can prevent premature wear and failures, contributing to the overall reliability of the machinery they support. Utilizing advanced monitoring technologies can also aid in identifying potential issues before they lead to significant downtime.

In summary, large forged gears play a pivotal role in the oil industry, providing the strength, durability, and performance necessary for efficient operations. Their ability to withstand extreme conditions and customizable nature makes them ideal for various applications within the sector. By understanding the importance and benefits of these components, industry professionals can make informed decisions that enhance operational efficiency while ensuring the reliability and safety of their equipment.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot