Why Large Forged Gears Are Essential for Oil Industry Applications

Release Time:

Aug 15,2025

Why Large Forged Gears Are Essential for Oil Industry Applications Table of Contents Introduction to Large Forged Gears Importance of Large Forged Gears in the Oil Industry The Manufacturing Process of Large Forged Gears Material Selection for Durability and Performance Applications of Large Forged Gears in Oil Extraction Benefits of Using Large Forged Gears Maintenanc

Why Large Forged Gears Are Essential for Oil Industry Applications

Table of Contents

- Introduction to Large Forged Gears

- Importance of Large Forged Gears in the Oil Industry

- The Manufacturing Process of Large Forged Gears

- Material Selection for Durability and Performance

- Applications of Large Forged Gears in Oil Extraction

- Benefits of Using Large Forged Gears

- Maintenance Considerations for Forged Gears

- Future Trends in Large Forged Gear Technology

- Conclusion

- FAQs

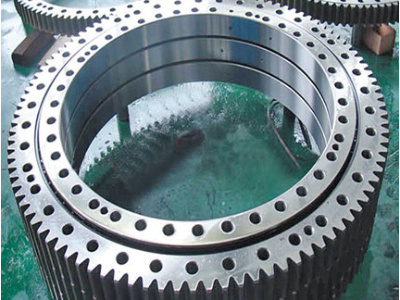

Introduction to Large Forged Gears

In the oil industry, robust machinery is crucial for efficient operations. Large forged gears are integral components that enable this machinery to function effectively. These gears, known for their strength and durability, are manufactured using a specific forging process that enhances their performance under extreme conditions. Understanding the significance of large forged gears helps in recognizing their pivotal role in oil extraction and processing.

Importance of Large Forged Gears in the Oil Industry

The oil industry faces rigorous demands, from offshore drilling platforms to refineries. Large forged gears are engineered to withstand high torque and heavy loads, making them essential for various applications. Their ability to operate smoothly under stress not only ensures the safety of operations but also maximizes productivity. In an industry where downtime can lead to substantial losses, the reliability of large forged gears is non-negotiable.

The Role of Gears in Oil Industry Operations

Gears play a vital role in numerous applications, including drilling rigs, pumps, and compressors. They facilitate the transfer of power from engines to machinery, converting energy efficiently. By using large forged gears, companies can enhance the overall performance of their systems, thereby reducing the risk of mechanical failure.

The Manufacturing Process of Large Forged Gears

The manufacturing of large forged gears involves several critical steps, each designed to produce a gear that meets stringent industry standards.

1. Forging Techniques

The forging process typically involves heating metal and shaping it under pressure. This process aligns the grain structure of the metal, which significantly improves its mechanical properties. Various techniques, such as open-die and closed-die forging, are used depending on the desired specifications.

2. Machining and Finishing

After forging, gears undergo machining processes to achieve precise dimensions. Techniques like CNC machining ensure that the gears meet exact tolerances, resulting in a smooth fit and operation. Finishing processes, including heat treatment and surface hardening, further enhance wear resistance.

Material Selection for Durability and Performance

Choosing the right material is crucial for the performance of large forged gears. Common materials include carbon steels, alloy steels, and stainless steels, each offering different properties suited for specific applications.

1. Carbon Steel

Carbon steel is often preferred for its excellent toughness and machinability. It provides a good balance between strength and ductility, making it suitable for various oil industry applications.

2. Alloy Steels

Alloy steels, infused with elements like chromium and molybdenum, enhance strength and corrosion resistance. These properties are vital for gears exposed to harsh environments, ensuring longevity and reliability.

Applications of Large Forged Gears in Oil Extraction

Large forged gears are utilized across various segments of the oil industry. Their applications range from drilling operations to refining processes.

1. Drilling Rigs

In drilling rigs, large forged gears are used in rotary tables and mud pumps. They help manage the immense loads and repetitive stresses encountered during drilling operations.

2. Pumps and Compressors

Pumps and compressors, essential for transporting oil and natural gas, rely on large forged gears for efficient power transmission. Their robust construction minimizes the risk of breakdown, crucial for maintaining continuous operations.

3. Refinery Equipment

In refineries, large forged gears are integral to machinery like distillation columns and heat exchangers. They ensure the safe and efficient processing of crude oil into usable products.

Benefits of Using Large Forged Gears

The adoption of large forged gears in the oil industry offers several advantages:

1. Enhanced Strength and Durability

The forging process imparts superior mechanical properties to the gears, making them capable of enduring high stresses and loads over extended periods.

2. Improved Efficiency

Large forged gears contribute to the overall efficiency of oil extraction and processing processes. Their precise design allows for smoother operation, reducing energy consumption and operational costs.

3. Resistance to Wear and Fatigue

Due to their material composition and manufacturing techniques, large forged gears exhibit exceptional resistance to wear and fatigue. This reliability reduces the frequency of replacements and maintenance.

Maintenance Considerations for Forged Gears

While large forged gears are built for durability, regular maintenance is essential to ensure optimal performance.

1. Regular Inspections

Conducting routine inspections helps identify wear and tear early, allowing for timely interventions that can prevent major failures.

2. Lubrication

Proper lubrication is vital to minimize friction and heat generation between gear surfaces. Following the manufacturer's guidelines on lubrication schedules can extend the lifespan of the gears.

3. Replacement Protocols

Having a clear protocol for gear replacement is crucial in maintaining operational continuity. Companies should establish criteria for when gears should be replaced based on their condition and performance metrics.

Future Trends in Large Forged Gear Technology

As the oil industry evolves, so does the technology surrounding large forged gears. Innovations in materials science and manufacturing processes are set to enhance gear performance further.

1. Advanced Materials

Research into advanced materials such as composite alloys could lead to stronger and lighter gears. These materials may offer improved resistance to corrosion and wear.

2. Smart Gear Systems

With the rise of the Internet of Things (IoT), smart gear systems that monitor performance in real-time may become commonplace. This technology could provide data that helps predict failures, allowing for proactive maintenance.

3. Sustainable Practices

As the industry moves toward more sustainable practices, the production of large forged gears may shift toward environmentally friendly processes. This would involve minimizing waste and reducing energy consumption during manufacturing.

Conclusion

Large forged gears are indispensable components in the oil industry, providing the strength, durability, and efficiency required for demanding applications. Their robust manufacturing process, coupled with careful material selection, ensures they meet the high standards necessary for operations in this challenging sector. As technology continues to advance, the future of large forged gears will likely bring even greater innovations that enhance performance and sustainability, solidifying their role in the industry for years to come.

FAQs

1. What are large forged gears?

Large forged gears are heavy-duty components made through a forging process, designed to withstand high loads and stresses, commonly used in the oil industry.

2. Why are forged gears preferred over cast gears?

Forged gears are preferred due to their superior strength, durability, and resistance to wear and fatigue, making them more suitable for demanding applications.

3. How do I maintain large forged gears?

Regular inspections, proper lubrication, and establishing replacement protocols are crucial for maintaining large forged gears.

4. What materials are commonly used for large forged gears?

Common materials include carbon steel and alloy steel, each offering properties suited for specific oil industry applications.

5. What are the future trends in large forged gear technology?

Future trends may include advanced materials, smart gear systems, and sustainable manufacturing practices aimed at enhancing performance and reducing environmental impact.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot