What are the influencing factors of iron castings?

Release Time:

Jul 13,2023

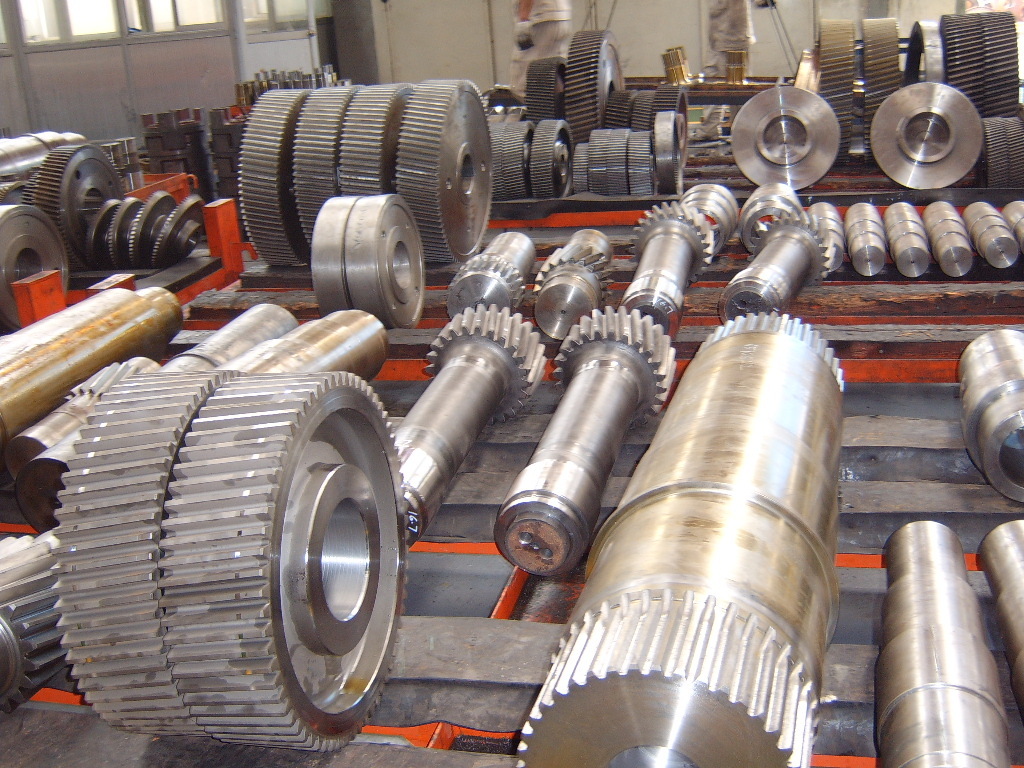

Do you know the influencing factors of iron castings? Let me tell you something. The influencing factors of cast iron are as follows: the first is the design process of iron castings. In the design, in addition to determining the geometric shape and size of iron castings according to working conditions and metal material properties, the rationality of the design must be considered from the point of view of casting alloy and casting process characteristics. that is, obvious size effect and solidification, shrinkage, stress and other problems, in order to avoid or reduce the composition segregation, deformation, cracking and other defects of iron castings.

Do you know the influencing factors of iron castings? Let me tell you something. The influencing factors of cast iron are as follows: the first is the design process of iron castings. In the design, in addition to determining the geometric shape and size of iron castings according to working conditions and metal material properties, the rationality of the design must be considered from the point of view of casting alloy and casting process characteristics. that is, obvious size effect and solidification, shrinkage, stress and other problems, in order to avoid or reduce the composition segregation, deformation, cracking and other defects of iron castings.

Second, it is necessary to have reasonable casting technology. That is, according to the structure, weight and size of iron castings, casting alloy characteristics and production conditions, the appropriate parting surface, modeling and core-making method are selected, and the casting reinforcement, cold iron, riser and gating system are set up reasonably. To ensure the availability of high quality iron castings.

The third is the quality of raw materials for casting. The quality of metal charge, refractory, fuel, flux, modifier, casting sand, molding sand binder, coating and other materials are not up to the standard, which will cause iron castings to produce defects such as pores, pinholes, slag inclusion, sand sticking and so on. affect the appearance and internal quality of iron castings, and scrap iron castings in serious cases.

The fourth is the process operation, it is necessary to formulate reasonable process operation rules to improve the technical level of workers, so that the process rules can be correctly implemented. In manufacturing production, the quality of castings should be controlled and inspected. First of all, it is necessary to formulate process codes and technical conditions from raw materials and auxiliary materials to the control and inspection of each specific product. Each process is controlled and inspected in strict accordance with the process code and technical conditions. Finally, the quality of finished castings is inspected. It is necessary to be equipped with reasonable testing methods and suitable testing personnel. Generally speaking, for the appearance quality of professional iron castings, the surface roughness of castings can be judged by comparing samples, and the fine cracks on the surface can be checked by coloring method and magnetic powder method.

Sheng hardware products set production and processing, research and development, technical services in one of the integrated enterprises. Feel free to contact us for more inquiries.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot