How does the foundry prevent the shrinkage of aluminum castings in production?

Release Time:

Jul 13,2023

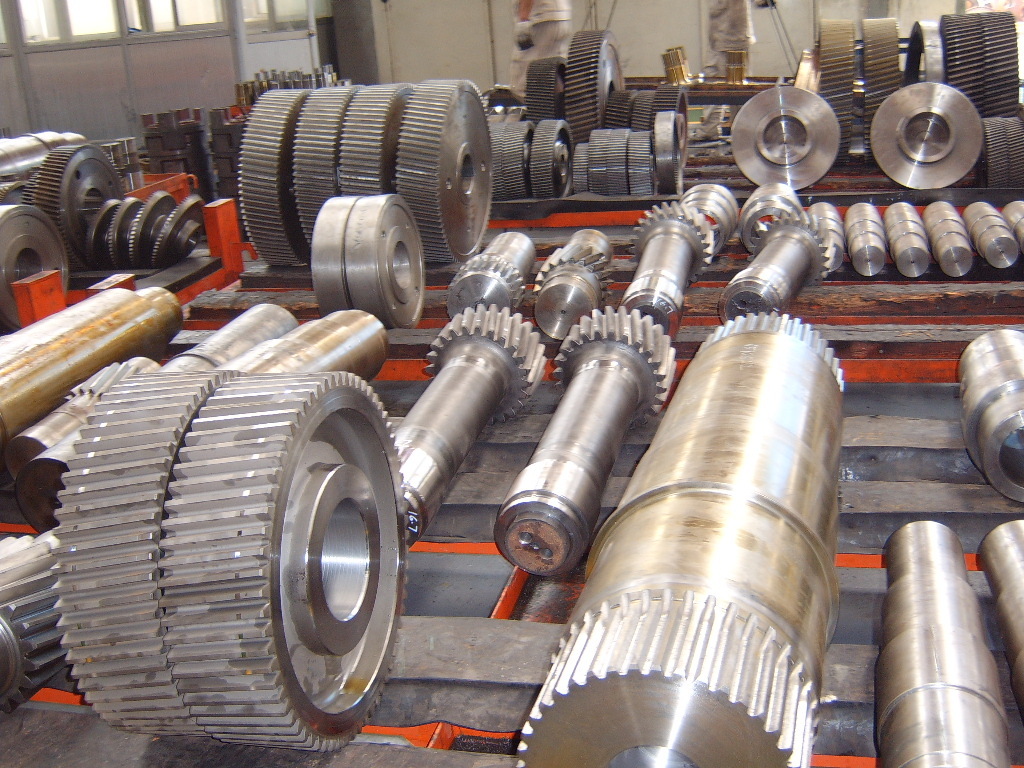

The basic principle to prevent shrinkage and porosity of castings is to establish a correct casting process according to the characteristics of shrinkage and solidification of the alloy, so as to establish good feeding conditions in the process of solidification, and convert shrinkage into shrinkage as much as possible. and make the shrinkage appear at the last solidification of the casting.

The basic principle to prevent shrinkage and porosity of castings is to establish a correct casting process according to the characteristics of shrinkage and solidification of the alloy, so as to establish good feeding conditions in the process of solidification, and convert shrinkage into shrinkage as much as possible. and make the shrinkage appear at the last solidification of the casting.

In this way, a riser of a certain size is placed at the final solidification place of the casting, and the aluminum casting concentrates the shrinkage hole in the riser, or the gate is opened at the final solidification place to make up directly. In order to establish a good feeding condition in the process of solidification, the main reason is to control the solidification direction of the casting to make it conform to the "directional solidification principle" or "simultaneous solidification principle".

The introduction position of gating system has an important influence on the temperature distribution of castings. Directional solidification or simultaneous solidification can be enhanced by adjusting the pouring temperature and speed of liquid metal.

The riser is set on the thick wall or hot joint of the casting, and the aluminum casting is the most effective technological measure to prevent shrinkage and porosity. The comprehensive application of riser, subsidy and cold iron is an effective measure to eliminate shrinkage and porosity in castings.

The cast iron handicraft is pressurized and compensated, the mold is placed in the pressure tank, and the pouring hole is quickly closed after pouring, so that the casting is solidified under pressure, which can eliminate or reduce the micro-shrinkage.

多行文本内容元素

富文本内容绑定数据后可解析HTML语言内容

Key words:

News Hotspot